Fluid Beds

Fluid Bed Dryers

FULLY AUTOMATED CONTROL SYSTEM UPGRADE FOR ANY SIZE GLATT FLUID BED DRYER

GENERAL DESIGN:

The ASC Glatt Fluid Bed Dryer Control System is designed for fluid bed dryers coating. The system is composed of two basic panels: a power panel, and an operator panel, or HMI (Human Machine

Interface). The power panel is typically remotely mounted in an accessible equipment room, while the HMI is typically mounted near, or on the coating pans itself. The system can control all functions associated with pan coating including airflow, temperature, differential pressures, dust collectors, air handling units, and spraying systems.

The Automation Sciences Corporation fluid be dryer control system is expandable to control server automated and manual functions. Precision metered control of granualization spraying is a common option. Wurster coating is another possibility. option with the addition of some hardware for additional solution management.

EASY ACCESS AND MAINTENANCE:

Both the power panel and the HMI panel are equipped with hinged doors for easy maintenance access. The system includes an upgrade to the coating pan drive system which includes a new Inverter duty gear

motor and a state-of-the-art belt drive and pulley configuration. This new drive system greatly improves reliability, reduces noise and reduces maintenance intervals and costs.

USER FRIENDLY:

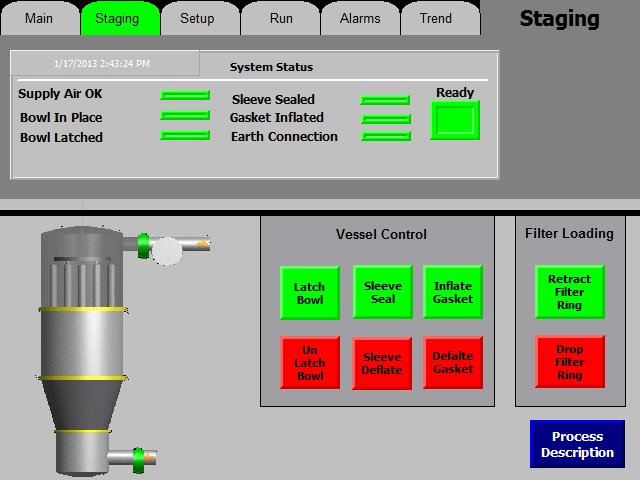

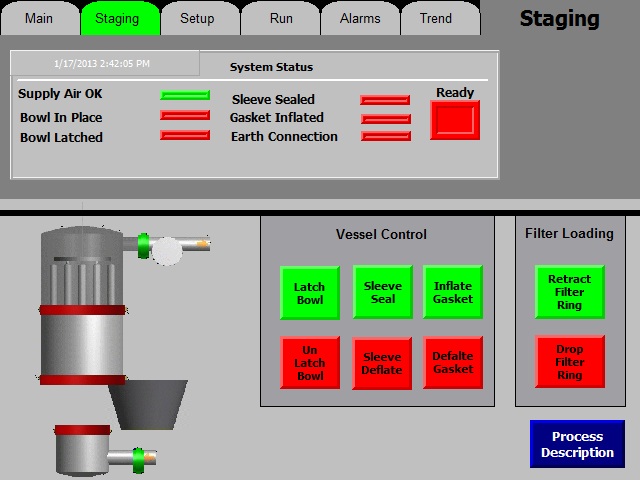

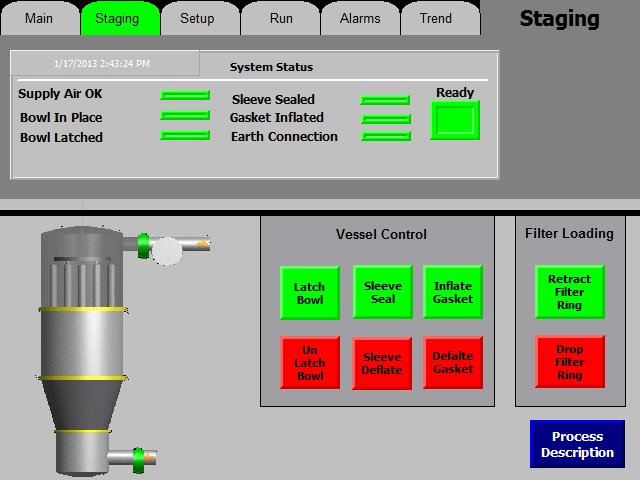

Our control and HMI user interface are designed from the ground up to be as flexible and more user-friendly than any system in the industry. The controls include optional features for just about any process variable that needs to be controlled for fluid bed drying. Manufacturers can choose the type of variables the system needs to control, and ASC will activate those options required to meet the end user's needs. All this in a single set of controls that can be delivered now, and reconfigured later as needs might progress. Provisions have been made in the hardware and software design to accommodate the expansion of features. These options can be activated as a Professional Service, rather than having to have a new set of controls built and delivered. Most features and functions can be optionally monitored via a network connection for convenience.

CONTROL SYSTEM DESIGN:

The design is based on fiercely reliable Rockwell / Allen Bradley components. The color touchscreen control system provides automated process control, recipe development, maintenance mode, and “log-in” security screens.. The printer allows process parameters to be recorded at intervals for post-process data analysis.

This system is also designed to accommodate Wurster coating

If 21 CFR Part 11 compliance is required, the control system can be upgraded to the ASC Glatt Fluid Bed Dryer Control 120E model, Automation Sciences Corporation’s most robust and complete control system. The Fluid Bed Dryer Control E automated control system offers automated process control and electronic data management that is consistent with 21 CFR Part 11.

EQUIPMENT FEATURES:

One (1) Operators console with 10” color touch screen

- IP65 NEMA 4 stainless steel enclosure

- 10” Allen Bradley wash-down touch screen

- Emergency stop button

- Power On/Off selector

One (1) system control cabinet equipped with

- IP65 NEMA 4 steel enclosure

- Allen-Bradley programmable logic controller

- Allen-Bradley analog I/O modules

- Power supply as needed

- Program PLC includes the following operations:

- Coating motor control with variable speed and soft start/stop

- Air handling temperature and flow control

- Inlet/Outlet/Bypass Pan temperature control

- Pan pressure

- Spray control pump speed

- Nozzle air control

- Product temperature readout

- Washing function

- Maintenance function

- Program HMI (Human Machine Interface)